How to Create a Synchronised Retail Supply Chain

Thu Aug 21 2025

Author

Noah Xiao

TL;DR: Every step in retail planning – sourcing, pricing, promotions, inventory, logistics, and workforce – either shapes demand or relies on demand. Without an accurate demand forecast at the centre, even the best plans risk being wasted effort. jahan.ai puts demand forecasting at the heart of a fully cohesive and synchronised planning suite, so every decision is connected and every plan is built on a common truth.

The Many Moving Parts of Retail Supply Chain Planning

Retail supply chain planning isn’t just one task – it’s a collection of interrelated functions spanning the entire journey of a product from supplier to customer. Some key components include:

- Demand Forecasting: Predicting what customers will buy, when, and in what quantities. It’s the backbone of planning, as every decision – sourcing, stocking, pricing – depends on an accurate forecast.

- Assortment Decisions: Choosing which products to stock and where. Assortment ensures the right range for each channel or location.

- Sourcing & Ordering: Securing supply by selecting suppliers, negotiating contracts, and placing orders. The aim is to have the right products at the right time – avoiding both excess stock and costly shortages.

- Network Planning: Deciding the best geolocation of stores and distribution nodes.

- Pricing & Promotions: Setting prices and campaign schedules that directly influence demand. Effective planning means forecasting uplift from promos and aligning with inventory, assortment, and shelf space.

- Inventory & Replenishment: Balancing availability and waste by setting stock levels, safety buffers, and replenishment schedules. Done right, it avoids both lost sales and markdowns.

- Logistics & Distribution: Moving goods efficiently from suppliers to stores or customers. This includes transport, routing, and scheduling to ensure products arrive on time and in the right place.

- Workforce: Planning workforce to match forecasted traffic. Even beyond the supply chain, operations hinge on demand signals.

Each area is usually managed by different teams – merchandising handles pricing and assortment, supply chain teams manage inventory and logistics, procurement manages sourcing. The challenge is that these parts are deeply interconnected. A promotion can spike demand, but only works if stock is ready. Switching to a cheaper supplier may extend lead times, which is fine only if forecasts and inventory plans adjust. In short, retail planning is a web of moving parts that must work in sync for the supply chain to run smoothly.

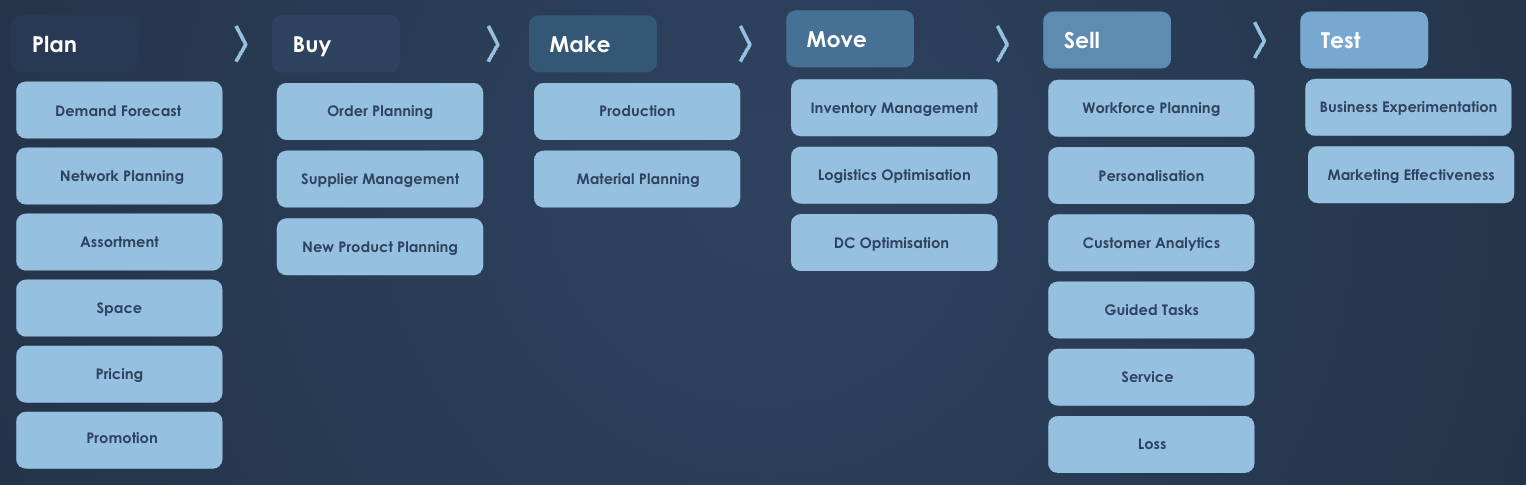

End-to-end value chain planning

The Danger of Planning in Isolation

Planning each part of the supply chain in isolation – without syncing data and decisions across functions – is a recipe for trouble. When merchandising, procurement, demand planning, and operations each do their own thing, mismatches are inevitable. You may end up with beautifully optimized sub-plans that, when put together, simply don’t mesh. Here are a few scenarios that illustrate why siloed planning is so dangerous:

- Mismatched Supply and Demand: If demand forecasts aren’t shared or are ignored by supply planners, you get the wrong inventory. The procurement team might commit to buying too much of a slow-moving item (wasting money and shelf space) or too little of a hot seller (causing stockouts and missed sales). Poor planning can wreck supply chain operations, increasing costs and frustrating customers . We’ve all seen empty shelves for a promoted item (because the demand surge wasn’t communicated), or conversely, piles of unsold inventory that had to be marked down because a buyer ordered excess without up-to-date forecasts.

- Conflicting Objectives: In silo, each function might optimize for its own goal at the expense of others. For instance, a sourcing manager might secure a bulk purchase discount (great for procurement costs) but inadvertently overload the inventory holding capacity or cash flow. The inventory team, measured on stock turn, might then slash orders to reduce stock – causing the retail operations to run out of product when marketing is running a big campaign. Without a unified plan, these well-intentioned actions undermine overall performance.

- Lack of Visibility and Slow Reactions: Siloed systems mean no real-time visibility across the chain. If each department is using separate spreadsheets or software, it’s hard to see the full picture. This leads to slow reaction times. For example, if a supplier delay occurs, in an isolated setup it might take days for that information to propagate to inventory planners and store teams – by which time empty shelves start hurting sales. A survey of supply chain executives identified lack of flexibility, higher costs, and poor responsiveness as major consequences of siloed operations . In today’s volatile retail environment, that’s a risk businesses can’t afford.

In essence, planning in isolation leads to a chain that’s out of sync. One weak link (or one department’s plan that doesn’t align) can throw off the entire system. You might hit your targets in one area (say, procurement got a great deal), but miss the ultimate goal: having the right product in the right place at the right time for the customer. The cost of these misalignments shows up as excess inventory or stockouts, expedited shipping fees to play catch-up, lost sales, and unhappy customers.

What a Synchronised Supply Chain Looks Like

Imagine a mid-sized supermarket chain, FreshMart, that has stores across the country. Like many retailers, it runs promotions, launches new products, manages thousands of SKUs, and has to keep shelves stocked while avoiding excess waste. Here’s how a synchronised supply chain looks in practice for them:

One Source of Truth

At the centre, FreshMart uses a single demand forecast. Every department – merchandising, supply chain, store operations – sees the same numbers. That forecast is continuously updated with sales, promo plans, and external signals. Instead of each team using their own spreadsheet, there’s one trusted view of expected demand. When it changes, it changes for everyone.

Cross-Functional Planning in Action

The merchandising team decides to run a two-week promotion on a popular cereal brand. Before locking it in, they simulate the uplift using the forecasting platform: if we discount by 20%, demand could rise by 35%. They test a few scenarios and choose the one that balances sales growth with margin.

Once the promotion plan is locked in, the new demand numbers automatically flow into other plans:

- Procurement and inventory teams see the uplift, adjust orders to suppliers, and secure transport slots ahead of time.

- Workforce planners know stores will be busier during the campaign, so they roster extra checkout staff and stock fillers.

Everyone is working from the same playbook, so there are no surprises when the campaign goes live.

End-to-End Visibility

At FreshMart, synchronisation isn’t just about sharing data, it’s about keeping planning cycles coherent. Merchandising locks in a promotion, the forecast updates, and that single number then drives procurement orders, logistics schedules, and workforce rosters.

Each team plans in sequence but off the same stable forecast, so efforts stay aligned. When changes happen – a supplier shortfall or stronger-than-expected sales – the forecast updates and cascades across all functions, giving everyone visibility and allowing them to adapt together. This creates a loop that’s dynamic but coherent, ensuring all departments plan with confidence.

Start with Demand: Forecasting as the Foundation

The starting point for end-to-end planning is always demand forecasting. It’s the upstream input that drives everything else – what to buy or produce, how to price, where to stock, and how to staff. If demand is wrong, every downstream plan will be wrong. Under-forecast and you under-buy, under-allocate, and miss sales. Over-forecast and you tie up capital, cut margins, and end up clearing excess stock. A credible forecast anchors the rest of the plan in reality, which is why demand planning is often called the backbone of the supply chain.

If you want to improve promotion planning, the first question should be: how do I know if this promotion will actually work as expected? That naturally leads to the need for a forecast, so you can predict performance, iterate, and refine your plan. The same applies to workforce: before building rosters or aiming for fairer schedules, you first need to ask: how many people will I need for each task, at each time? – again, a demand forecast provides the answer.

Modern retailers are moving beyond gut feel or simple trend analysis to AI-driven forecasting. Machine learning can combine sales history, seasonality, promotions, weather, search data, and even market trend and competitor actions to create more accurate, granular forecasts. Studies show this can cut forecast errors by 20 – 50%, directly reducing stockouts, markdowns, and wasted spend. Crucially, a good forecast also supports scenario planning – testing “what if” cases like promo uplifts or supplier failures, so teams can build contingency plans before issues hit.

Perhaps most importantly, demand becomes the common focal point across departments. When marketing, merchandising, supply chain, and operations all plan against the same demand view, silos start to break down. Forecasting isn’t owned by one team – it’s a collaborative process that integrates inputs from across the business. Used in the right way, it creates alignment, turning isolated plans into a synchronised system where every function is pulling in the same direction. In short: start with demand, and you set the stage for everything else to work.

Creating a Cohesive Chain with jahan’s Integrated Planning Suite

Achieving this level of synchronised planning might sound daunting, but it becomes far simpler with the right technology. That’s exactly why we built jahan.ai’s product universe – a connected suite designed to bring every part of retail planning and execution together around one common thread: demand forecasting.

At the heart of our platform sits a forecasting engine that acts as the single “brain” for the business. Every module in the suite — whether it’s pricing and promotion, assortment and space, order planning, inventory optimisation, logistics, or workforce scheduling — draws from the same, continuously updated forecast. This ensures that when demand changes, the update ripples instantly across the entire chain. Merchandising sees the impact on promotions, supply chain sees it in orders and stock flows, operations see it in rostering and site needs — all working from one version of the truth.

Because everything is connected, retailers can move seamlessly from planning to execution. Promotions can be simulated to see their effect on demand, and once locked in, that revised forecast drives procurement, transport, and workforce planning automatically. Store operations, warehouse tasks, and even new product launches stay aligned because they’re grounded in the same demand signal. What once required siloed tools and manual reconciliation now runs in a single environment, with far less firefighting.

The result is a supply chain that doesn’t just plan in pieces but plans as a whole. By anchoring all decisions to demand, jahan.ai enables retailers to maintain higher on-shelf availability, reduce excess inventory, optimise pricing and promotions, and staff stores fairly and efficiently — all while responding quickly when the market shifts. It’s a modern, AI-powered approach that turns disconnected processes into a cohesive, resilient system.

jahan.ai Product Suite

Takeaway

In today’s fast-moving retail world, planning in isolation is no longer an option. Retailers that synchronise every link of their supply chain — from demand and supply to merchandising, logistics, and execution — achieve fewer stockouts, faster responses, and better service at lower cost. It all starts with a strong demand forecast and the right tools to break down silos. At jahan.ai, we help retailers build one unified plan that keeps the whole business moving in sync.

Reach out to us at info@jahan.ai to learn how we can help you get there.

#aiml

#aiTwin

#demandForecasting

#retail

#supplyChainPlanning